If you do choose you intend to have your range of scale calibration as soon as it arrives, where you go! Some are calibrated as soon as monthly, others are only calibrated once per year, while some even test daily for precision. Historically, calibration has been specified as a procedure of contrasting and videotaping indicated obtained from a measuring tool with the matching acquired when making use of measurement requirements.

Factors:

Typically, after taking into consideration these factors, it’s established that someplace between licensed calibrations when per quarter with a regular individual spot check is optimal to guarantee quality control of scales that are made use of relatively typically. Nevertheless, your demand may vary based on the info below.

Constantly consult the manufacturer’s recommendations first. Producers must have a recommendation for the regularity of calibration, and also because all scales are made differently, it’s generally risk-free to think the supplier recognizes best.

Dimension tools:

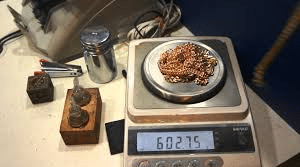

Considering instruments/scales/balances, they are widely utilized in industry for numerous measurements. Some considering instruments are small research laboratory instruments determining a couple of grams as well as are extremely precise. While some commercial weighing tools are large ones that procedure, for instance, the mass of vehicles. All of us see evaluating tools in our day-to-day life around us, for example, when we go to a grocery store as well as evaluate vegetables.

As with any type of dimension tool, considering instruments should likewise be calibrated regularly to assure that they are gauging properly and precisely. A correct metrologically deducible calibration is the only method to recognize exactly how accurately weighing instruments are determining. For example, when adjusting a bench range, the shown value from checking out the range display screen can be compared to the worth of the examination weight. This can be corrected by a series of weights, and also a calibration table can be developed that records showed values from the range and also equivalent values gotten from the different examination weights used.

Calibration test:

When a well-known weight is applied the indicator has to display the precise amount of used weight within a specific resistance. When weight is used or removed incrementally the range should show the weight equal to that on the scale within the specified resistance mentioned above. The enhancing tons examination as well as lowering lots test together with corner screenings would certainly be ideal in numerous scenarios.

We are in some cases asked exactly how to check or examine accuracy or exactly how frequently to execute range calibration, as well as the answers, can vary depending upon your scenario. To check the scale, you simply put a product on the range as well as see what it evaluates. Preferably this would be a licensed test weight. An additional instance maybe if you have a mobile vehicle range, you ought to probably adjust that scale every time you relocate from one place to one more location. Or at least examine it with a known weight to ensure the accuracy is still acceptable.