Scale Calibration: Your Complete Guide

Scale calibration is very important because an inaccurate Scale could damage the business. Even in the laboratory setting, the results are totally dependent upon the exact weight. So you can see how important scale calibration is.

Calibration is the process of Testing the Scale to ensure the level of accuracy.

It is observed that even the highest quality of scale cannot be accurate for a more extended period. There can be inaccuracy due to certain situations like if this scale is exposed to mechanical or electric shock or if the scale is exposed to the environment when there are oils, Metal Chips, and moisture. And if these conditions occur, this could lead to further damage to your business because inaccurate measurements could further Result in quality issues of product, prescription batches, and even a product recall.

Table of Contents

Process of Calibration

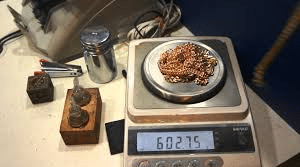

As already said that calibration is a process of testing the scale just to ensure the level of accuracy needed. Now the question arises of how does the whole process of calibration works. In simple words, the certified mask is placed on the scale. Then the reading of the weight is recorded. If the weight readings match the calibration tolerance standards, then there is no need for any adjustment. But if the weight readings do not match, then there is undoubtedly the need to restore the scale to the acceptable state of accuracy.

It is found that an instrument can be used to measure a particular range of weight. It is known as the instrument range. So the specific instrument can or cannot be calibrated for the entire field. Instead, there may be a calibration range which ranges from 0 to a maximum weight. When the calibration range is defined, to ensure higher accuracy, the calibration is done at several points from 0 to span, which Means from 0 to maximum weight you have chosen.

Now the question arises what the factory calibration is? How often should you calibrate your scales? What is illegal for trade calibration?

Difference between Calibration and Adjustment

There is an essential difference between calibration and adjustment. We should not get confused between these two terms:

Calibration

The international bureau of weights and measures (BIPM) And a joint committee for guides in metrology (JCGM) both created a tool to help in monitoring the standardization of weighing terms. This is called the international vocabulary of metrology (VIM). In simple words, we can say that scale is calibrated to understand how it behaves. Calibration is a quantitative comparison. It is a process of testing the scale and to ensure the level of accuracy needed.

Adjustment

Adjustment means the setting of measuring deviations are made small. Adjustment needs an intervention that alters the measuring instrument or scales permanently.

Types of calibration?

Factory calibration

When you buy a scale, it comes with factory calibration. Now understand this term factory calibration. It merely means that it was calibrated before you receive your scale. For example, when the scale was manufactured, it was kept in the factory and then for a few days. After that, it was calibrated. You got it after another few days. Use and fully assume that it was calibrated and ready to put in use. But here is a point to understand. The factory’s location and the location where you are going to use that scale, two different places. You can say to different elevations. So simple, you have to do on-site calibration to ensure that your scale is accurate.

Third-party calibration services

Once you have decided that you want your scale to be calibrated, the question arises where should you go? Here is the answer.

Third-party calibration services. To ensure that third-party calibration services are trustworthy or not, your main aim is to restore your scale to its original, optical accurate state. There are some third-party calibration services available in the market. They will not only calibrate the scale but also adjust repairs if needed.

How often should you calibrate your scale?

How often Your Scale should be calibrated depends upon different factors. You have to consider the recommendations of the manufacturer of the scale. The environment in which the scale is being used. How often the scale is used for measurement. And the most important factor is how exact weight is essential for your business’s credibility. Some scales are calibrated once a year; others are calibrated once a month. But there are scales that are not even spot checked on a daily basis.

After going through these factors, it is considered to do the calibration once per quarter with a weekly user spot check. This type of checking is ideal to ensure the quality control of scales that are in regular use but you can also consult the recommendations of the manufacturer. The manufacturer’s recommendations should be considered important as they know the best of their scales and need to calibrate them. If your scale is being used many times frequently in a day, then there is a possibility of normal wear and tear faster than the scales used a few times or a limited time in a week. So frequently use the scales need frequent calibration.

The environment in which the scale is used plays an important role. If the scale is being used in an area where dust or fluid particles or other substances are present, then your scale could be affected by these things as the scale could have a buildup of these substances and could further interfere with the performance of the scale. Suppose your scale is being used in an area where there are static electricity and mechanical shock or the presence of vibrations. In that case, the accuracy of the scale is indeed suffering.

So, it would be best if you went for a frequent calibration to keep away these effects on your scale.

Now come to the Point, which directly affects your business. And that is how an accurate weight is important for the credibility of your business. If your company cannot afford to have the slightest accuracy in weight, frequent calibration is needed. For example, in a pharmaceutical blending of ingredients, a mistake in weighing could cost more like it could exceed even $1,00,000 per batch. You can now imagine that a truck loaded with the quarry rocks and stones could cost more. Now you must be thinking that if a small error of 2% can make such a big difference? The answer is yes. It may not cost much if you think of one load, but if you are thinking of hundred trucks every day with the same error, I hope you can now understand the amount of loss your business will be facing.

When you have decided on the scale calibration, you can sign a service plan with the calibration company at this point.

What is calibration tolerance?

International Society of Automation (ISA) defined calibration tolerance as “Permissible deviation from a specified value, maybe ex-president measurement units, percent of Span or percent of reading.” So tolerance guide ensures that your scale measures the weights within a range that will not damage or tarnish your business. The manufacturer will specify accuracy and tolerance for your scale in particular. But it would be best if you did not depend on this only to determine the calibration tolerance.

Besides, manufacturers specified tolerances you should also keep in mind the following points:

● Your process requirements

● Regulatory accuracy and maintenance requirements

● Consistency with similar instruments

For example, your process requires +5 g, test equipment is capable of +0.25 g. So the manufacturer’s accuracy for your scale is 0.25 g. It means your specified calibration tolerance Needs to be between the process of the requirement of +5 g and manufacturers and tolerance of +0.25 g. In a nutshell, the calibration tolerance should be consistent with the other, similar instruments or scales.

Legal for trade calibration

Commercial scales need to be legal for trade calibration. To elaborate it more, it means that the scales need to be calibrated according to the established standards of “specifications, tolerance and other technical requirements of weighing and measuring devices.” It is also known as “handbook 44”. This comprehensive list of requirements is necessary for all scale is used for commercial purposes.

Every year, the National Institute of standards and technology Publishes a new version of it. When you are using your steel for commercial purposes, you surely need legal for trade calibration. Let’s understand with the help of an example, at the grocery store, you are chicken, cheese, or pulses weighed on a scale. The weight determines the price. So the grocery store scale is an example of a commercial scale. A state of weights and measures inspector makes sure that your scale for commercial use should be appropriately calibrated. If not, then your device can be tagged and taken out of service.

Need to register the weighing device

Many states require to register your scale of commercial use with the state. The state should also approve the scale. Most states accept skills that are supported by national type evaluation program. NTEP approved scales get a certificate of conformance. This approval document is in the form of a metal plate or tag on the scale with the make, information regarding capacity and model number. If you have the conformance certificate and your scale has all the standards and tolerance of “handbook 44”, your scale will pass the inspection.

How to register a weighing device?

Any professional calibration service company can help you to register your device. If you want to do your own, you can contact your state for registration through online and offline applications. The registration fee can vary from state to state. For example, If you are in Pennsylvania or New Jersey, you can contact the following addresses:

Pennsylvania weights and measures inspection

2301 North Cameron Street

Harrisburg, PA 17110. 717-787-9089

New Jersey Office of Weights and Measures

1261 Route 189

Avenal, NJ07001

How to choose A company to Calibrate scale?

When looking for an accredited calibration company, make sure the team is experienced in scale calibration and educated enough to understand what the process needs and further make you know the necessary formalities. Certification by the International Society of weights and Measures gives you the required assurance that the technicians have the experience, capabilities, and knowledge to perform the calibrations.

The CWT program requirements include experience in scale calibration, formal NIST H-44 training and the requirement of passing a written exam. In addition to this, the technician has to re-certified every 5 years. So before choosing, look for these required qualities in the company to calibrate the scale. You must expect good documentation practices, honesty, integrity and knowledge of calibration processes.

Calibrate the Analogue Weighing Scale

This is easy to calibrate. You need to stand directly above the weighing scale and look at the dial. The measuring line should align with 0. But it does not then look for the dial behind the display. You will see a small calibration dial. Rotate it in the required direction till it aligns with the marketing for 0. This way, the analog weighing device will be aligned.

Calibrating the Digital Weighing Scale

These are scales that have auto-calibrations. So there is no need to calibrate these weighing scales. After every measurement, the weighing scale calibrates itself every time.

Benefits of scale calibration

Cost savings:

A calibrated scale helps in making sound decisions and further avoids wastes or product recall.

Compliance:

Calibration facilitates smooth and hassle-free external and internal audits.

Reliable measurements:

When we use calibrated equipment, this ensures that one place’s measurements are genuinely compatible with those made in another place. And results received from this process will be accurate and trustworthy.

Detection of ageing equipment:

The scales and types of equipment wear and tear with the passage of time. This aging or wear and tear can be detected through periodic calibration.

Process and Profit:

When the scale is calibrated, it gives increased profits.

I hope I made it clear how important is scale calibration. So, why risk your business built with hard-earned money face loss just for this little factor?