All scales calibration preferably requires to be adjusted when top place into the solution to ensure exact operation. Any range will drift away from its original calibration in time. The use of mechanical parts age and also the level of usage, all contribute to calibration drift. Several states call for that any type of range made use of to get or offer based upon weight has to be approved and checked and certified regarding its accuracy.

Calibration of a scale is a procedure in which a licensed range specialist uses known weight certified by the State of North Carolina Bureau of Weights as well as Actions, to adjust the feedback of a mechanical or electronic evaluating system to the following tests; the sign must reveal zero when there is no weight on the range.

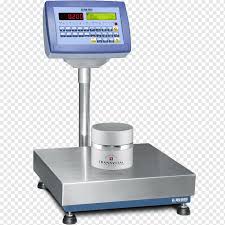

Weighting tool:

When a known weight is applied the indicator must present the exact quantity of applied weight. When weight is used or eliminated incrementally the scale has to display weight equivalent to that on the range display screen. Before you can begin the calibration of the weighing tool, you should clear up a few things and obtain prepared. Ultimately, consider exactly how vital an exact weight is to your company. If your firm can not afford to have even the tiniest error in weight, likely, even more, regular calibrations will certainly be essential.

The weighing instrument ought to be switched on a minimum of thirty minutes before the calibration. The temperature level of the weights needs to be supported to the same temperature where the calibration is to be done.

Evaluating tool:

Next off let’s have a look at the different tests that ought to be done throughout the calibration. The evaluating tool needs to go to a straight level, specifically for little and exact weighing tools. Carry out a couple of pre-tests by putting weights close to the optimum of the range on the tool and to guarantee it works usually. In instance the considering tool falls short in calibration as well as it is adjusted, you must make an “as discovered” calibration before adjustment as well as an “as left” calibration after adjustment.

All ranges preferably need to be adjusted when top place right into service to ensure the exact procedure. Any type of range will certainly wander away from its initial calibration in time. Wear of mechanical elements, age as well as level of use, all add to calibration drift. Generally, we suggest calibration every quarter by an educated scale service technician with certified examination weights.

Price of scale calibration:

If your ranges are made use of several times throughout the day, every day of the week, normal damage will certainly take place faster than in ranges that are made use of a couple of times each week. As a whole, you need to also think about a much more frequent calibration to make certain these materials as well as various other workplace variables are not hindering from obtaining a specific weight.

It might be understandable the relevance of accuracy when blending pharmaceutical ingredients where an error in weighing a solitary batch might conveniently exceed $50,000 in price. However, what about rocks and rocks from a quarry where a truckload could only be worth a few hundred bucks.